Maximizing Throughput: Precision Capacity Calculation for the Mobile ship unloader

- 1 Defining Capacity: Peak vs. Average Throughput Rates

- 2 The Material Factor: Calculation of Mobile ship unloader capacity based on material density

- 3 Technology Comparison: Continuous vs grab Mobile ship unloader TPH analysis

- 4 Optimizing Continuous Systems: Focus on Volumetric Efficiency

- 5 Hangzhou Aotuo Mechanical and Electrical Co., Ltd.: Pioneers in Bulk Handling Efficiency

- 6 Frequently Asked Questions (FAQ)

- 6.1 1. What is the fundamental difference between peak and average capacity in a Mobile ship unloader?

- 6.2 2. Why is the bulk density of the material essential for the Calculation of Mobile ship unloader capacity based on material density?

- 6.3 3. What is the primary advantage of a continuous unloader over a grab unloader according to a Continuous vs grab Mobile ship unloader TPH analysis?

- 6.4 4. How is the volumetric filling factor optimized in a screw unloader?

- 6.5 5. What factors are prioritized in Operational cycle time optimization for mobile unloaders for grab systems?

Efficient port logistics depend on the reliable and rapid unloading of bulk cargoes. For the **Mobile ship unloader**, throughput—measured in tonnes per hour (TPH)—is the single most critical performance metric. Engineering the equipment to maximize this rate requires detailed analysis of material characteristics, system dynamics, and the intrinsic differences between continuous and intermittent unloading technologies. This deep dive provides technical insights into optimizing capacity, addressing the key Factors affecting ship unloader average versus peak capacity.

1000-70000 DWT 200-1500t/h Tire Mobile Screw Ship Unloader

Defining Capacity: Peak vs. Average Throughput Rates

When evaluating performance, it is vital to distinguish between peak and average capacity.

Understanding Factors affecting ship unloader average versus peak capacity

- **Peak Capacity:** The theoretical maximum instantaneous flow rate achievable under ideal, steady-state conditions (e.g., when digging into a full, undisturbed cargo pile in the center of the hatch).

- **Average Capacity:** The true operational performance over the entire unloading period. This rate is inevitably lower due to necessary non-productive time, including hatch change time, cleanup cycles, and adjustments for the ship's geometry and trim. These factors are central to understanding Factors affecting ship unloader average versus peak capacity.

Capacity Calculation: The Role of Bulk Density and Material Flow

The TPH calculation begins with volumetric flow. The mass flow rate is determined by multiplying the system's volumetric capacity (cubic meters per hour) by the actual bulk density (tonnes per cubic meter) of the material being handled. Accurate capacity guarantees rely heavily on precise input data regarding material characteristics.

The Material Factor: Calculation of Mobile ship unloader capacity based on material density

Material density and flowability are the primary variables dictating achievable mass flow.

Formulaic Approach: Volumetric Flow Rate to Mass Flow Rate (TPH)

- The TPH formula is TPH = QVol×ρBulk, where QVol is the volumetric throughput (m3/h) and ρBulk is the actual in-situ bulk density (t/m3). When performing the Calculation of Mobile ship unloader capacity based on material density, the assumed density must account for compaction within the ship's hold.

The Impact of Material Abrasiveness and Stickiness on Performance

Materials like clinker or iron ore are highly abrasive, potentially requiring reduced operating speeds to protect components and avoid excessive wear. Conversely, sticky materials (e.g., certain types of coal) can reduce the effective cross-section of the conveying system, lowering the volumetric flow rate and thus impacting the accuracy of the Calculation of Mobile ship unloader capacity based on material density.

Technology Comparison: Continuous vs grab Mobile ship unloader TPH analysis

The fundamental operational difference between continuous and intermittent technologies drives variations in achievable average throughput.

Intermittent (Grab) Unloaders: Efficiency and Operational cycle time optimization for mobile unloaders

- Grab unloaders operate intermittently, meaning the capacity is defined by the grab volume and the total cycle time (grab penetration, hoisting, slewing, discharging, and return). Optimizing Operational cycle time optimization for mobile unloaders is essential; factors like hoist speed and operator skill directly impact the average TPH.

Continuous (Screw/Bucket) Unloaders: Volumetric Efficiency and Flow Stability

Continuous unloaders (CSUs), such as those using screws or bucket elevators, maintain a steady flow, eliminating the non-productive time associated with the grab cycle. As highlighted by a Continuous vs grab Mobile ship unloader TPH analysis, CSUs typically boast a higher average TPH relative to their peak capacity, especially when handling free-flowing materials like cement or grain.

Intermittent vs. Continuous Unloader Performance Table

| Unloader Type | Throughput Characteristic | Primary Limitation on Average TPH |

|---|---|---|

| Grab (Intermittent) | High Peak, Low Average | Non-productive time in cycle, cleanup phase |

| Screw/Bucket (Continuous) | Consistent High Average | Volumetric filling factor, material flowability |

Optimizing Continuous Systems: Focus on Volumetric Efficiency

For continuous unloaders, the key to maximizing TPH is optimizing the efficiency with which the conveying elements handle material.

Achieving Maximum Maximizing screw unloader volumetric filling factor

- The volumetric filling factor is the ratio of the actual volume of material carried by the screw or bucket to the theoretical maximum volume. Maximizing screw unloader volumetric filling factor requires precise control of the digging head speed relative to the conveying speed, minimizing backflow, and designing the spiral geometry to match the material's angle of repose and fluid characteristics.

Belt and Screw Conveyor Speed Synchronization

In a continuous **Mobile ship unloader** system, all components—from the digging tool to the final discharge conveyor—must be perfectly synchronized. Any bottleneck or mismatch in speed will lead to material backup at transition points, effectively reducing the entire system's TPH to the rate of its weakest link, demonstrating the importance of continuous flow stability.

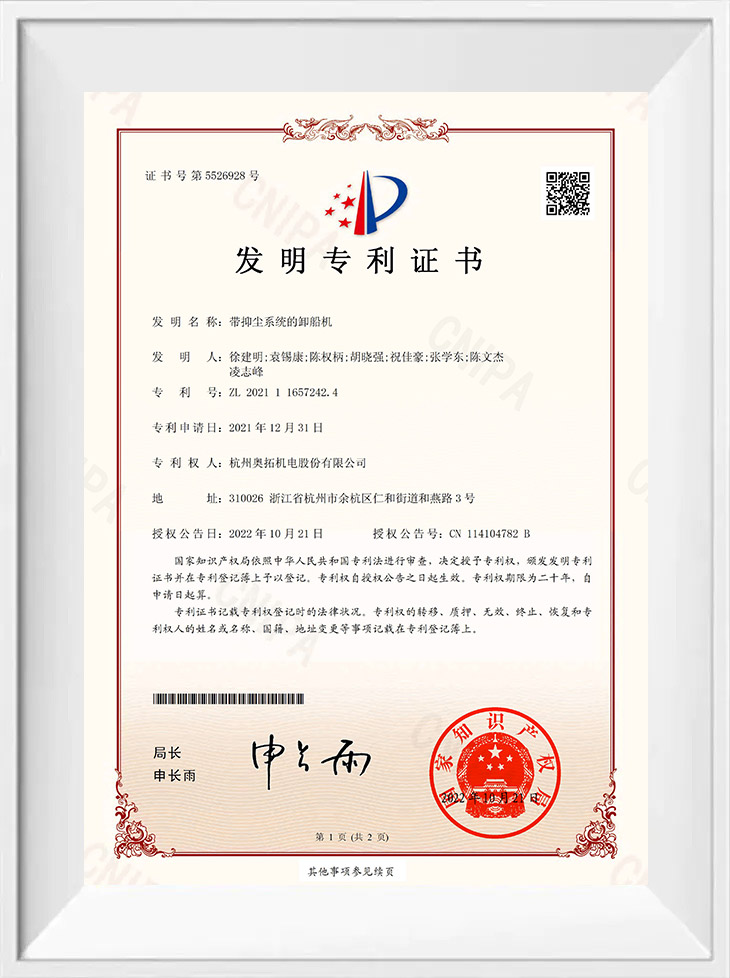

Hangzhou Aotuo Mechanical and Electrical Co., Ltd.: Pioneers in Bulk Handling Efficiency

Hangzhou Aotuo Mechanical and Electrical Co., Ltd. (AOTUO), established in 2003, is a national high-tech enterprise focused on comprehensive solutions for dry bulk material port transfer systems. With 20 years of R&D and manufacturing experience, AOTUO specializes in highly efficient and environmentally friendly screw unloaders and related equipment, including bulk cement, coal, clinker, and grain unloaders. Our technological leadership is evidenced by over 100 patents and our role as the drafting unit for the industry standard JC/T 2575 "Bulk Cement Spiral Unloader." Our unloaders achieve capacities up to 3000 t/h and can serve ships up to 200,000 DWT. We leverage our expertise to ensure our clients benefit from optimal performance, achieving maximum Maximizing screw unloader volumetric filling factor and providing detailed data for the accurate Calculation of Mobile ship unloader capacity based on material density. Our commitment is to provide the most efficient bulk handling solutions, validated by rigorous Continuous vs grab Mobile ship unloader TPH analysis.

Frequently Asked Questions (FAQ)

1. What is the fundamental difference between peak and average capacity in a Mobile ship unloader?

Peak capacity is the maximum instantaneous rate under ideal conditions, while average capacity is the rate achieved over the entire unloading period, accounting for non-productive time like cleanup and hatch changes, which are the main Factors affecting ship unloader average versus peak capacity.

2. Why is the bulk density of the material essential for the Calculation of Mobile ship unloader capacity based on material density?

Capacity is usually measured in tonnes per hour (TPH), a mass flow rate. The calculation converts the system's volumetric throughput (m³/h) into TPH by multiplying it by the material's bulk density (t/m³).

3. What is the primary advantage of a continuous unloader over a grab unloader according to a Continuous vs grab Mobile ship unloader TPH analysis?

Continuous unloaders (screws/buckets) eliminate the non-productive time associated with grab cycles (hoisting, slewing, discharge), resulting in a significantly higher average throughput rate relative to their peak capacity.

4. How is the volumetric filling factor optimized in a screw unloader?

Optimization for Maximizing screw unloader volumetric filling factor involves designing the screw geometry to match the material's flow characteristics and precisely controlling the speed of the digging tool relative to the conveyor speed to minimize internal backflow.

5. What factors are prioritized in Operational cycle time optimization for mobile unloaders for grab systems?

Priorities include high hoisting and slewing speeds, accurate positioning (to minimize unnecessary travel), and rapid discharge mechanisms, all of which reduce the overall cycle time and improve the average TPH.

News Category

Recommended Products

It is focused on the overall solution of dry bulk material port transfer system,

research and development, manufacturing, and service

- WhatsApp: +86-13675892653

- Tel: +86-18958022558(Timmy You)

- +86-13675892653(IVY Zhou)

- E-mail: [email protected]

- Add: No. 3 Heyan Road, Renhe Base, Qianjiang Economic Development Zone, Yuhang District, Hangzhou City

Copyright © Hangzhou Aotuo Mechanical and Electrical Co., Ltd. All Rights Reserved. Custom Material Conveyor Transfer Systems Manufacturers

EN

EN English

English 中文简体

中文简体 Français

Français